Wet Cement Stock Photos And Images 123RF

Download Wet cement stock photos. Affordable and search from millions of royalty free images, photos and vectors.

WhatsApp)

WhatsApp)

Download Wet cement stock photos. Affordable and search from millions of royalty free images, photos and vectors.

Evolution of the cement Process Wet process easiest to control chemistry amp; better for moist raw materials. Wet process high fuel requirements fuel needed to evaporate 30+% slurry water. Dry process kilns less fuel requirements Preheater/Precalciner further enhance fuel efficiency amp; allow for high production rates. 17.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement ki...

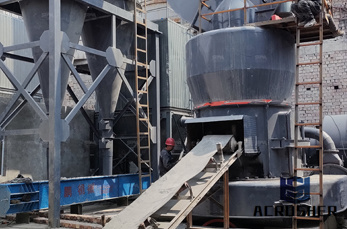

Cement Production C Wet Process Images. Ore Beneficiation Plant. New dryprocess cement plant is composed of raw materials crushing equipment, Classification Code SCC for portland cement plants with wet process kilns is 305006 and the sixdigit SCC for plants with dry process kilns is 305007.

Burning : In this operation, the slurry is directly fed into a long inclined steel cylinder called Rotary kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones : In the wet process, the drying zone is comparatively larger than dry process. In is because the raw material in slurry form is directly fed into the kiln which has

Manufacturing of Cement By Dry and Wet Process. Oct 29, 2019#183; Different manufacturing techniques will use either wet or dry grinding, but each cement manufacturing process will culminate in heating and fine grinding to finish the product.

Cement manufacturing process image Home / Manufacturing of Cement By Dry and Wet Process / Cement manufacturing process image

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter.

#0183;#32;The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process. Also Read: OPC vs PPC: How to Make the Right Choice. Tanvi Lad. Tanvi Lad is a Senior Manager (Civil).

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

#0183;#32;The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure The limestone is disintegrated in crushers. The crushed limestone is fed to a tube mill, where the limestone and the clay, introduced as a slurry from a

Fig: Manufacture of Cement by Dry Process. b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos. The clay is then washed in washing mills to remove adhering organic matters found in clay.

Find the perfect Wet Cement stock photos and editorial news pictures from Getty Images. Select from premium Wet Cement of the highest quality.

Your Cement Wet stock images are ready. Download all free or royaltyfree photos and vectors. Use them in commercial designs under lifetime, perpetual amp; worldwide

Manufacturing the cement kiln Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter.

#0183;#32;Other articles where Wet process is discussed: cement: Manufacture of cement: manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to form nodules that are fed to

The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixing.

WhatsApp)

WhatsApp)