Waste Water Recycling Wash Plant AquaCycle CDE

The CDE AquaCycle thickener allows you to recycle up to 90% of the process water from your wet classification and washing plant

WhatsApp)

WhatsApp)

The CDE AquaCycle thickener allows you to recycle up to 90% of the process water from your wet classification and washing plant

#0183;#32;Explore CDEGlobal''s photos on Flickr. CDEGlobal has uploaded 2921 photos to Flickr.

4 Methods to Improve the Grade of TBS Fine Coal and Get Good Economic Benefit. The traditional separation technique of coking coal is, heavy dense medium cyclone processing, fine particle flotation, the mature separation technology based on coarse coal heavy dense medium process and slurry flotation has been formed.. As the developing capacity of coal washing plant, the

Multotec is an industry leader in metallurgy and process engineering, helping mining houses across the world process minerals more efficiently, effectively and reliably.

Safe carriage of Iron ore amp; other iron concentrates in bulk Iron ore is used for the production of metallic iron in steelmaking. Although some 45 countries export natural iron ore resources, seven countries provide 75% of the total exported. The two largest exporters are Brazil and Australia, with about 33% of total world exports each.

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, highquality fine ore powders, are known as fines. Magnetite. Magnetite is magnetic, and hence easily separated from the gangue minerals and

tailings recycling KMAruda washing plant Iron Ore and Pig Iron division and Powder Metallurgy division. Ownership of the coal and iron ore extraction and processing capacities is the base for unique quality of IMHs products purity and low costs. IMH is the largest global exporter of merchant pig iron and the biggest Russian

#0183;#32;iron ore washing plant from CDE Asia in India including Prograde screens, conveyors and Evowash fines washing plant

#0183;#32;Stoilensky GOK Pellet Plants . Russia . Iron Ore Pellet. Novolipetskiy metallurg. komb. OAO. Taiyuan Iamp;S Pellet Plant . Sand Washing Plant equipments India iron ore beneficiation plant equipments manufacturers. November 26, Fine Iron ore Indian origin, st... Industry, Company Introduction, policies,

Commissioned in late 2017, the two CDE processing plants wash, separate and gravity beneficiate about 17 Mt of low grade overburden iron ore that was stockpiled in waste dumps into a highgrade saleable product with a 63% iron content upgraded from an average lowgrade grade of between 45% and 50% iron content in the waste dumps, explains Warren.

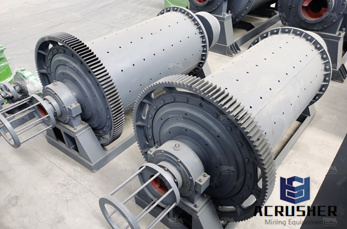

used mini washing plant for iron ore in Russia heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

DENSE MEDIUM SEPARATION AN EFFECTIVE AND ROBUST PRECONCENTRATION TECHNOLOGY *Erin LegaultSeguin1, Curtis Mohns1, Mike Rylatt2 1SGS Canada Inc. 182 Concession St. Lakefield, ON K0L 2H0

The study aimed at investigating the chemical composition and microstructure of raw iron ore from the deposits in Muko area (southwestern Uganda). The quality of this iron ore was evaluated to establish its suitability to serve as a raw material for iron production. Samples were taken from the six hills of Muko ore deposits and tests carried out to establish their composition and properties.

Ironore fines were decreasing kiln campaign life by forming accretion in the kiln as well as affecting fuel efficiency adversely. The benefit that CDE Projects brings to the table is the ability to cope with the varying nature of the feed while still delivering significant improvements in product quality by way of increase in the Fe value and close sizing devoid of deleterious fines.

#0183;#32;Vallourec''s beneficiation plant produces concentrated iron ore lumps and fines in Pau Branco mine . Tailings are composed of both fines (gt;45 m) and ultrafines (lt;45 m). Ultrafines are generated from the desliming cycloning of the magnetic concentration process, and fines

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process.

Russia was in fifth place worldwide in iron ore production in 2008, after China, Brazil, Australia, and India. The main area of production, yielding over half of all Russia''s iron ore, is the Kursk Magnetic Anomaly in the Central district with four large ore deposits. Other iron mines exist in

WhatsApp)

WhatsApp)