Solid End Mills Kennametal

Kennametal solid end milling products are designed to deliver higher productivity, longer tool life, and increased application versatility.

WhatsApp)

WhatsApp)

Kennametal solid end milling products are designed to deliver higher productivity, longer tool life, and increased application versatility.

Your toughest technical questions will likely get answered within 48 hours on ResearchGate, the professional network for scientists.

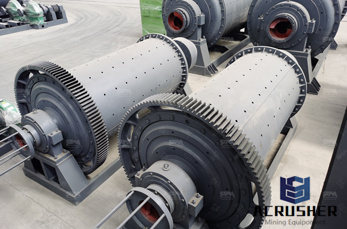

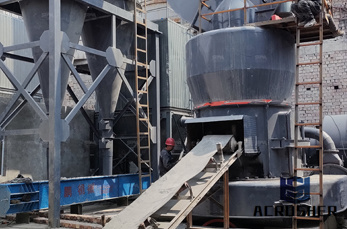

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ball Mill In Powder. Ball mill is an efficient tool for fine powder grindinghe ball mill is used to grind many kinds of mine and other materials, or to select the mine ball mill is widely used in building material, chemical industry, etchere are two ways of grinding the dry way and the wet wayt can be divided into tabular type and.

Large Capacity Professional Ball Mill Machine picture from Shanghai Clirik Machinery Co., Ltd. view photo of Ball Mill Grinding, Ball Mill, Milling China

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical

(Milldust is the term that is used for BP as it comes straight out of the ball mill, before any granulation.) Second Step I take 16 ounces of the pine charcoal milldust, add ounces of water (10%) to it, and thoroughly incorporate the water into the powder with my gloved hands. Then I further incorporate the water with a screen colander.

Professional Copper Silica Powder Ball Mill Design From China. Energy Saving Professional Copper Silica Powder Ball Mill Design Capacity:/h Finial size:80025m Processible Materials:Gypsum, limestone, etc. Application:Ore, slag, stone, silicate product,

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

A method capable of manufacturing, by using a ball mill apparatus, powdered tea having the same quality as that manufactured by using a millstone. By using the ball mill apparatus having synthetic resin pots, a powdered tea material and synthetic resin balls are sealed in the pot, and the pot is revolved or revolved and rotated on its axis to crush the powdered tea material.

Melin offers a large variety of both Carbide and Cobalt HSS end mills. These series are offered with a variety of coating and end style options. Melin continues to expand the product line with improved geometry and coating options. General Purpose 2, 3, amp; 4 Flute Carbide End Mills Square, Ball, Corner Rounders; Powdered Metal End Mills; NC

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill''s motor compartment, you can now see the motor, with a small fan and pulley on its shaft. That small pulley is connected by a drive belt to a large pulley which is mounted on the unit''s drive

End Mills Responding to demand for lower processing costs and shorter lead times, as well as your need to process diverse work pieces and to reduce environmental impact. As your partner in manufacturing excellence, Nachi America supports you in an everevolving environment, where you need to win the process challenges of increased efficiency, increased precision, and increased functionality.

Looking for OSG Ball End Mill, 1 in, Powdered Metal, Bright (Uncoated), NonCoolant Through (35DC32)? Grainger''s got your back. Price Easy online ordering for the ones who get it done along with 24/7 customer service, free technical support amp; more.

A Ball Mill is a rotating drum with dozens of lead balls inside. The 3 chemicals are loaded into the Ball Mill, along with the lead balls, sealed shut and allowed to rotate for anywhere between 1 hour and 24 hours. As the Ball Mill rotates, the lead balls will crush the chemicals together, forcing some of the Potassium Nitrate into the pores of

Looking for OSG Ball End Mill, 3/8 in, Powdered Metal, Bright (Uncoated), NonCoolant Through (35DA96)? Grainger''s got your back. Price Easy online ordering for the ones who get it done along with 24/7 customer service, free technical support amp; more.

WhatsApp)

WhatsApp)