Industrial Roller Manufacturers | Roller Design and

Manufacture industrial rollers with innovative processes. Talk with an engineer to improve your roller designs and manufacturing process. ISO 9001:2015 REMAN Council Veteran Owned Business

WhatsApp)

WhatsApp)

Manufacture industrial rollers with innovative processes. Talk with an engineer to improve your roller designs and manufacturing process. ISO 9001:2015 REMAN Council Veteran Owned Business

You can successfully rollform a profile more than one way. In fact, many roll form designers take different approaches to design and development. Also, because the roll forming process has a seeming limitless capacity to produce complex profiles with just as many variables, many roll form designs are oneofakind; therefore, theory can go only so far.

in the design of gear teeth to transmitand use the power. A typical case would involve the design of the gearing for a hoist to raise a certain weight (W) ata uniform speed, when making use of a motor with a given horsepower (hp) running at a given speed (rpm) and

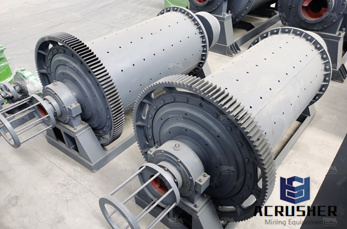

Figure 6: The Roll Mill Assembly 22 31. Figure 7: Work Piece Figure 8: The Roll 23 32. Figure 9: The Roll Figure 10: The assembly and the parts list 24 33. 8 Conclusion The aim of this design project was to design a geared twohigh rolling mill and model it

MAEG3040 MECHANICAL DESIGN Problem Set #5 Due: March 22, 2016 1. A geared industrial roll shown in the figure 1 is driven at 300 rev/min by a force F acting on a 3indiameter pitch circle as shown. The roll exerts a normal force of 30 lbf/in of roll length on the material being pulled through. The material passes under the roll.

2. Design Analysis and Calculations Roll Crusher Geometry It is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a known roll diameter, roll length and roll gap. It is convenient to assume that the particle is spherical and the roll

Design a geared industrial roll mill SlideShare. Mechanical Engineering Design III assignment involving the design of a geared industrial roll (two high). The roll is driven at 350 rev/min by a force F ac #187; Learn More. Roller mill roll futing design

The purpose of this booklet is to set out the basic design for an industrial gearbox. It should help students not familiar with gearboxes, lay out a reliable working design. And it is intended for the reader to use his own experience in selecting formulae, stress values etc., for gearbox components.

Industrial Gearboxes Visit Our Products Website. NGC delivers products for vertical mill reducers, roll mill reducers, center drive cement mill reducers, and kiln reducers implemented in fluid pumps, compressors, and fan equipment. With advanced designs and high product quality, NGC constantly creates greater value for the petrochemical

Prob. 7#226;4, A geared industrial roll shown in the figure is driven at 300 rev/min by a force F acting on a 3indiameter pitch circle as shown. The roll exerts a normal force of 30 lbf/in of roll length on the material being pulled through. The material passes under the roll. The coefficient of friction is

A geared industrial roll shown in the figure is driven at 300 revymin by a force F acting on a 3indiameter pitch circle as shown. The roll exerts a normal force of 30 lbfyin of roll length on the material being pulled through. The material passes under the roll. The coefficient of

MAEG3040 MECHANICAL DESIGN Problem Set #5 Due: March 22, 2016 1. A geared industrial roll shown in the figure 1 is driven at 300 rev/min by a force F acting on a 3indiameter pitch circle as shown. The roll exerts a normal force of 30 lbf/in of roll length on the material being pulled through. The material passes under the roll.

DESIGN LIMITS FOR ROLLS..... 99 BENDING STRESS which are more or less very normal for rolling mills roll damage often occurs with consequences for the mill and the rolled product. Evidently the reasons of roll failure have to be discussed and

#0183;#32;The scope of project covers the following stages: 1) Analysis of geared drivelines design (12 stands) along with technological schedules and maintenance procedures of hot rolling mill.

Intelli Power Geared Motor World class quality based on the latest European technology at Indian prices. High power transmissiontoweight ration facilitating easy handling. Being modular in design, can be used with any other standard motor. Range: Power range from to 55kw Size: From 16mm to 110mm output shaft diameter

design a geared industrial roll mill. rolling mills tmt bar gear box design cold rolling . PP Rolling MillsManufacturer hot rolling mill tmt bar steel rolling steel rolling mill gear box design cold rolling gear reduction gear reduction box rotary shear heavy engineering Media In order to meet the enhanced reliability and delivery requirements of the growing industrial

A geared industrial roll shown in the figure is driven at 300 revymin by a force F acting on a3indiameter pitch circle as shown. The roll exerts a normal force of 30 lbfyin of roll lengthon the material being pulled through. The material passes under the roll. The coefficient offriction is

The original geared motor required a high degree of maintenance, demanding the tanks basin be emptied twice a year. This resulted in production losses and high maintenance costs. The original supplier had designed a solution that employed a singlestage bevel gearbox fully submerged in

WhatsApp)

WhatsApp)