(PDF) COPPER PRODUCTION WITH OUTOKUMPU

The history of making blister copper in an Outokumpu Flash Smelting Furnace dates back to the late 1960''s, when Outokumpu first piloted the Outokumpu Direct Blister (ODB) process.

WhatsApp)

WhatsApp)

The history of making blister copper in an Outokumpu Flash Smelting Furnace dates back to the late 1960''s, when Outokumpu first piloted the Outokumpu Direct Blister (ODB) process.

For copper metallurgy,Metalcess supplies low investment copper blast furnace for Copper ore/copper sulfide ore/coppernickel sulfide ore smelting to produce copper anode.

New Flash Copper Smelter In 2010, it began the construction of a new flash copper smelter with a projected capacity of tons of concentrate per year. The modernization of copper smelter includes replacement of the old roaster/ reverberator furnace with more efficient autogenous flash smelting process.

Flash smelting takes place autogenously in flash furnace 21 at a temperature of at least about 1350#176; C. to produce a lime ferrite slag 23, semiblister copper 12 and a sulfur dioxiderich gas 24. The semiblister copper is tapped as a product and slag phase 23 is tapped and passes to copper recovery unit 28.

02 Flash smelting furnace The copper concentrates are fed through the flash smelting furnace with oxygenenriched air. In the furnace, the concentrates are instantly oxidized, after which they melt and separate by their own reaction heat into copper matte with a grade of 65% and slag consisting of iron oxide, silica, and other compounds.

#0183;#32;Blast Furnace 5 Life Extension Project Salamander Tap Duration: 1:15. Kennecott Ut Copper Visitors Center Video Duration: 4:36. RED POINT DIGITAL LLC 9,771 views.

Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace. Molten copper is poured from here into rectangular moulds, the resulting ingots subjected to electrolysis producing a metal of % purity. Copper can be recycled indefinitely without the base metal being compromised

#0183;#32;old kennecott smelter in garfield ut I take no credit for this video in anyway shape or form other than uploading it to share its history.

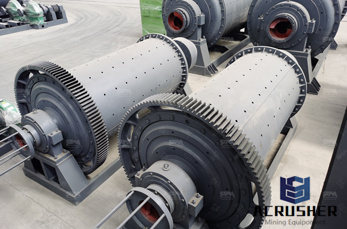

#0183;#32;Shows the conversion of copper ore and concentrates into metallic copper. The operations depicted include crushing and sampling of the ore; mixing with conce...

#0183;#32; What is FLASH SMELTING? What does FLASH SMELTING mean? FLASH SMELTING meaning FLASH SMELTING definition FLASH SME...

Flash smelting (Finnish: Liekkisulatus, literally quot;flamesmeltingquot;) is a smelting process for sulfurcontaining ores including process was developed by Outokumpu in Finland and first applied at the Harjavalta plant in 1949 for smelting copper ore. It has also been adapted for nickel and lead production.. A second flash smelting system was developed by the International Nickel

#0183;#32;Mini Furnace Furnace Smelting Scrap Copper Copper Gold Silver Aluminum IRIS Import amp; Export Co., Ltd We are professional research and production enterprise with

#0183;#32;How can a smelting furnace smelt the copper ore to blast copper, welcome to contact nikki for more information.

#0183;#32;Then the thermodynamic model of the copper flash continuous smelting process will be developed, and be used to discuss the advantages and disadvantages of the structure of the four furnaces for copper continuous smelting. 2 Furnace description According to the different flowing way of the molten smelting slag and the gas, the copper flash continuous smelting furnace can be

Process Flow Description: Concentrates and other copper bearing material are blended and conveyed from two separate areas of the plant to three 464 ton capacity wet charge bins located above the rotary dryer. Flash furnace silica flux is conveyed to a 250 ton capacity fine flux bin located adjacent to the wet charge bins. The concentrate and flux are blended in controlled amounts and fed into

Moreover, the flash smelting process simulation results show that the reaction shaft design should be optimized based on a combination of furnace dimension and type of concentrate burners. Keywords Flash furnace, flash smelting, copper concentrate, particle fragmentation, combustion

#0183;#32;Use the mini gas propane kiln (for sale) as a copper melting furnace to make a copper ingot while working at home on your art, jewellery of recycling project...

WhatsApp)

WhatsApp)