CITICHeavy Industries Co. Ltd

CITIC HIC has received an order for Ball Mill #216; x LG 7,100kW, This mill will operate at the Itatiaiucu Expansion Project in Brazil. 20 November 2010 CITIC HIC Engineering Building,...

WhatsApp)

WhatsApp)

CITIC HIC has received an order for Ball Mill #216; x LG 7,100kW, This mill will operate at the Itatiaiucu Expansion Project in Brazil. 20 November 2010 CITIC HIC Engineering Building,...

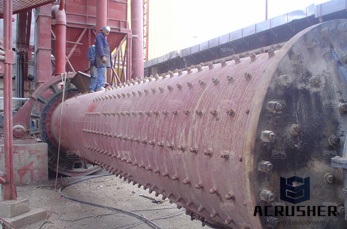

Ball mill is a kind of grinding mill used in the mineral processing, which is to further grinding the material fitness to the appropriate particle size that meets the industrial requirement after the crushing process. At present, the ball mill machine is widely used in mine, cement, silicate products, building materials and other fields. 1. Structure of ball mill

Ball milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase. 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig. ), under wet or dry instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant. 22 Graphite (50 g) was ground in

Advantages and features of the ceramic ball mill. The grinding fineness depends on the milling time. The motor of the ceramic ball mill is started by the coupling reduce voltage which lowers the starting electricity and the ball mills structure is divided into integral type and freestanding type; advantages of the ceramic ball mill are lower investment, energy saving, structure novelty

ball mill manufacturer brazil Description. Ball Mill Manufacturers, Ball Mill Dealers and . Ball Mill Our company is one of the progressive amp; prominent manufacturers and exporters of Ball Mill . Our offered range is widely accredited b y the clients due to features such as smooth operation, longer service life and less power consumption.

The main components of the ball mill Earlier in the overall structure of the several types of mill. The following will introduce the basic structure of the main components of the mill. Rotary Rotary parts include: cylinder,energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate,...

Ball Mill Manufacturers In South Brazil Concrete crushing machine capacity 2000 tph. crusher for iron ore for capacity of 1000 t r for crusher with capacity 500 1000 tph is used as big up the complete 500 tph magnetite iron r capacity 1000 hoavai used jaw crusher capacity 1000 th jaw crusherjaw breakerjaw crushersstone crusherrock jaw crusher is one of the crushing machines

Cement Ball Mill Structure. When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the

Chocolate ball mill machine is ideal chocolate mass milling equipment, smart design and compact structure guarantees the most smoothly chocolate texture. Chocolate Ball Mill Machine Chocolate ball mill machine is designed for milling chocolate cream or similar oilbased products by the frictions between high quality 68mm steel balls.

: Ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. is committed to designing, producing grinding mills, crushers, conveyors, feeding machines, drying and calcinating as well as beneficiation equipments and etc, which are

brazil al ore ball mill. A Review of Advanced Ball Mill Modelling Know More. Keywords: modeling, discrete element method, ball mills, mechanistic function (Si) to predict grinding in a batch mill using the equation (Austin et al., 1984) This is because the powder or ore particles are much finer in size than the of the faculty of the Universidade Federal do Rio de Janeiro (Brazil) since 1998

14/1/2019#0183;#32;Structurally, each ball mill consists of a horizontal cylindrical shell, provided with renewable wearing liners and a charge of grinding medium. The drum is supported so as to rotate on its axis on hollow trunnions attached to the end walls (attached figure 1 ball mill). The diameter of the mill determines the pressure that can be exerted by the

ball mill / Raymond Mill Main Structure Brazil Raymond Mill Main Structure Brazil . Brazil arcelormittal brasilprised of 27 facilities and awork with more than 110 units the countrys facilities have a steel production capacity of 113 million tonnes and iron ore production capacity of 71 million tonnes with over 11,Raymond Mill Main Structure Brazil.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

(1) Types on the Basis of Cylinder. 1. Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, the ball mill with L 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in series.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

WhatsApp)

WhatsApp)