Angle Grinder Risk Assessment Template HASpod

RISK ASSESSMENT Use of Grinders Classico Marble

WhatsApp)

WhatsApp)

RISK ASSESSMENT Use of Grinders Classico Marble

9. Do not leave angle grinder running amp; only use the grinder when hand held. 10. Do not touch work piece immediately after grinding operation as it will be extremely hot. 11. Avoid breathing dust wear suitable dust mask or respirator in dusty areas. 12. Don''t overreach or work at an awkward angle. 13.

Risk Assessment Management Contact with an angle grinder or ejected materials can cause burns, entanglement, fractures, lacerations, amputation and serious injuries to you, your employees and /

the risk assessment in the staffroom and made it part of the induction process for new staff. The owner decided when the actions that were needed would be done, and who would do them, and decided to tick the actions off as each was completed.

This site task risk assessment form for using a disc cutter or grinder/abrasive wheel machine will allow you to assess the risks to your employees while carrying out this task. This risk assessment form has been professionally written for you to use by adding to or

Pre Control Risk Ratings Post Control Activity Hazard Risks Risk Ratings 1* 2** 1#215;2 Control Measures 1* 2** 1#215;2 Comments Noise Assessment required where deemed necessary. A safe working platform is required when using a power tool (in preference to equipment such as a step ladder).

Risk Level Medium Control Measures Hearing protection must be worn. KEY OPERATING INSTRUCTIONS OPERATION 1. Always ensure machine is turned off at the power source before attempting to change cutting wheels. 2. Always use both hands when operating the grinder. 3.

COMPANY: Baseline Risk Assessment HAZARD IDENTIFICATION AND RISK ASSESSMENT amp; RISK RATING COMPILED BY: Sanchia Taylor must be identified for use on site. All angle grinders and surface cutting machines must be identified and entered on a register / checklist.

This risk assessment deals with grinding using hand held grinders, including at height. This is suitable for on site, or inside a workshop. We recommend the Grinding Method Statement to go with that. Its just #163; + VAT. Add both Basket. COSHH Assessment. 114 Latex .

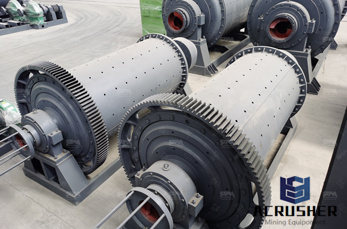

Grinder Machine Hazards All types of grinding machines, whether pedestal, bench mounted, freestanding or portable, can be potentially hazardous if they are not well maintained and used correctly. In addition to the common hazards of flying particles, dust and sparks, shattering abrasive wheel while in Motion can cause severe injury to both the user and others.

Do not lift or drag angle grinders by the cord. Keep flexible electrical cords clear of oil, grease, machines and sources of heat. Be aware of flying sparks. Hold grinder so that sparks fly away from you, other people and flammable materials. DO NOT LEAVE THE ANGLE GRINDER RUNNING amp; ONLY USE THE GRINDER WHEN HAND HELD.

Bristol Hackspace Risk Assessment Bench Grinder use. The workshop is not generally supervised and lone working is allowed. Workshop users generally show a lack of awareness of adjacent activity. Induction is required before use but the induction process unclear and record keeping is poor.

KMA Ltd. Issue 1/11. August 2011. Completion of this document converts it into a site specific assessment. To be reviewed in August 2012. Page 1 of 2 Risk Assessment Part A Generic Hazards Risk Assessment Ref: Activity: Working with Hand Tools Client: Site: Date of Assessment: Hazards Harm Risk prior to Control Measures Persons at Risk

A large angle grinder may only be use for cutting purposes following the completion of form T1559. Risk Management The use of angle grinders, in particular for cutting purposes, should be specifically considered in the Job Safety and Environmental Analysis (JSEA) for the task, to ensure risk associated with the work is at an acceptable level.

Risk Assessment A risk assessments for a pedestal or bench grinder always includes a core set of recognized hazards and requirements. The discussion below describes each hazard, points out the related OSHA requirements, and makes suggestions for remediation.

Risk Assessment Part A Generic Hazards Risk Assessment Ref: Activity: Abrasive Wheels (Type 27, 41, 42) Time to Use Residual Risk Angle grinders lt; 1500 W 30 min Low 90 min Medium Angle grinders 1500 W 30 min Low 60 min Medium All times above are TRIGGER TIMES, TOTAL

When grinding metals 125 mm dia. When grinding tools with discs gt;115 mm are designed with a spring loaded trigger switch ( NOT a sliding toggle switch). When grinding metals securely held in a vice. When grinding large, stable metal projects that do not require securing.

Confirm workers are fully trained and competent to use an angle grinder, and are aware of the sites strategy for reducing the risk of handarm vibration syndrome. Provide adequate supervision for those required to use an angle grinder. Supervisors and workers Conduct a taskbased risk assessment before commencing work and review it if work

RISK ASSESSMENT Use of Grinders Changing grinding, forming, polishing discs or wheels. (cont) machine and cau injury. Damaged abrasive wheel fitted causing potential to explode off se 4 3 12 If abrasive wheel is dropped it must be taken out of use and disposed of as wheel

WhatsApp)

WhatsApp)