micro grinding conventional machines

MicroGrinding Systems, Inc. | EnergyEfficient Vibratory Mills

WhatsApp)

WhatsApp)

MicroGrinding Systems, Inc. | EnergyEfficient Vibratory Mills

Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines. Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry. Grinding machines fall into five categories: surface grinders, cylindrical

Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines. Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine

An Excellent Balance of Precision Micro Machining and Cutting Efficiency. To address opposing demands, quot;precisionquot; and quot;quick deliveryquot;, #181;V5 exhibits high degree of versatility ranging from cutting customtailored ultrafine tools to highefficiency cutting of generalpurpose tools.

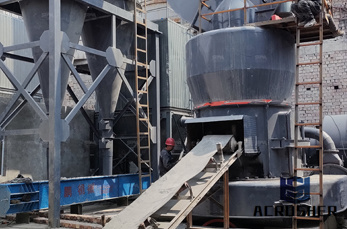

micro grinding conventional machines; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding

Nagel Introduces Nagel FLP Flat Lapping and Micro Grinding Machines. High Volume Honing Machines . Nagel builds both conventional stroke honing machines as well as single pass precidor honing systems. Proper honing technology is selected based on the part. Every machine is custom designed specifically

A conventional centerless grinder pulls the part through the machine by the work and regulating wheels. To grind a profile, the part''s position is detected by sensors and the gap between the wheels

micro conventional grinding machines in armenia. CNC Needle Grinding MicroGroup part of TE Connectivity employs a broad range of CNC tip grinding machines and techniques to produce highly precise tips for needles and other pointed parts from trocars and lancet to bevel and custom designs...We are a professional mining machinery manufacturer

The micro tool is fabricated by conventional micro turning process and thereafter micromachining is carried out by microEDM process.

Industrial Machining Services at Elan Technology micro grinding conventional machines,For ceramics, we offer a range of services,get price Grinder for MicroSized Tools : Modern Machine Shop The Walter Helitronic Micro combines a new design with linear motors to achieve 30 percent faster speeds and as much as 50 percent better surface finishes than machines with conventional balllead screws,

Superior grinding and sanding results are attributable to an extremely rigid machine base, a microfine stepless linear feed with hydraulic oscillating axle and precision guideways in longitudinal and transverse direction Wide travels allow machining of various workpiece diameters up to 320 mm and workpiece lengths up to 2 m.

MicroGrinding Systems, Inc. The VibroKinetic Energy (VKE) Mill is designed to fill the need for a fine to ultrafine grinding mill which is both low cost and economical to operate. Optional features include air

Minitool Micro Drills: Series 125151 SPADE type Solid micro grain carbide microdrills have (.125quot;) diameter and 38mm (quot;) overall length. They are available in sizes from .025mm (.001quot;) diameter to .50mm (.020quot;) diameter. Tolerances: Shank diameter: (.125quot;) +.0000quot;.0005

There are many applications for micromachining such as: Microfluidics, where tiny channels for the fluids are machined. Microwaves, where the frequencies are so high that signals travel in tiny waveguides rather than through wires. These waveguides are often micromachined.

The machine includes a threespindle grinding head for up to twelve wheels. And the Micro''s new Baxis positions the wheel to grind clearance angles with the samepoint on the wheel throughout the grind. These features help to speed up grinding by 30% and improve surface finishes by up to 50% than machines with conventional balllead screws.

CNC Needle Grinding. MicroGroup, part of TE Connectivity, employs a broad range of CNC tip grinding machines and techniques to produce highly precise tips for needles and other pointed parts, from

Apr 19, 2013#0183;#32;Turning. Micro screws are commonly produced on automatic screw machines. The threads can be cut with vgroove tools such as with conventional threads, with thread chasers (disclike holders with three or more mini cutting points), with button thread dies, or with thread rolling tools.

micro grinding conventional machines micro grinding conventional machines. P r a g a T o o l s Machines Conventional. PRAGA is one of the leading Machine Tool manufacturing units in India. Established in 1943, Praga''''s products are well known in the field of Machine Tools. Micro Drilling and Punching Machines.

Micromatic Grinding Technologies. Established in 1973, Micromatic Grinding Technologies Pvt Ltd (MGT) today manufactures a wide range of External, Internal, Universal and special purpose cylindrical grinders in CNC, PLC and Hydraulic versions to the exacting requirements of our customers from its 3 plants in Ghaziabad near New Delhi.

WhatsApp)

WhatsApp)