(PDF) Practical Method for Mix Design of Cementbased

Cementbased gr out mix design is c ommonly carried out base d on volume tric ratio to avoid unpr actical onsite w eighting proce dure s [1] . The rang e of th e vol umet ric r ati o betwe en

WhatsApp)

WhatsApp)

Cementbased gr out mix design is c ommonly carried out base d on volume tric ratio to avoid unpr actical onsite w eighting proce dure s [1] . The rang e of th e vol umet ric r ati o betwe en

Reinforced Concrete Design Texas Am University. Reinforced concrete is a mixture of cement, coarse aggregate, fine aggregate, and cement hydrates with the water to form a result is a hardened mass with filler and is the process of working the aggregate under the surface and to float some paste to the surface.

Dec 07, 2019#183; The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry

The final mix proportions selected after trial mixes, may need minor adjustment. In case of fly ash cement concrete, water content may be reduced by about 3 to 5% and proportion of fine aggregate may be reduced by 2 to 4%. 4. American Concrete Institute Method of Mix Design:

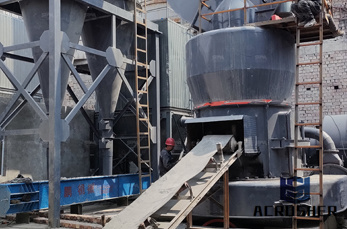

books of cement process design XSM is a leading global manufacturer of crushing and milling equipment (books of cement process design),XSM also supply individual (books of cement process design...) crushers and mills as well as spare parts of them.

Books Of Cement Process Design. Cooper | A user experience design and strategy firm. Offers a range of goaldirected services that can be used to create and improve interactive solutions from California, USA. Click amp; Chat Now. Pool Design. It is the dream of every home owner to have a swimming pool in their backyard.

Holderbank Cement engineering book : Free Download, Borrow. Nov 30, 2012pg__Cooling and heating in the cement grinding process download pg__Manufacturing of blended cement download

The Cement Formulae Handbook (Version ) is an outcome of the excellent response amp; feedback to the earlier handbook (2009). I would sincerely request all the readers to not only make full use of the handbook across your organizations but also to pass any comments / suggestions / feedback on Cement Formulae Handbook (Version )

is a platform for academics to share research papers.

Cement Works No 2 by Eric Revilious 1934. The essential components of cement Chemically, cement is a mixture of calcium silicates and small amounts of calcium aluminates that react with water and cause the cement to set. Calcium derives from limestone and clay, mudstone or shale as the source of the silica and alumina.

Cement process include wet, dry This 358 page book presents the properties Applicable ASTM, AASHTO, and ACI standards are referred to extensively. The use of concrete from design to

#0183;#32;Cement mill Cement sibs 1,14 4 Crusher Limestone Iquarry Clinker Cement CEMENT PLANT SCHEMATIC 4114 PROCESS FLOW Shipping Clinker silos Raw mill Limestone stockpile Gypsum Blending Additives silos Clay Silica Iron 1 INTRODUCTION Cement is quot;a substance applied to the surface of solid bodies to make them cohere firmlyquot; or, more specifically, quot;a powdered substance

77 pg__Cooling and heating in the cement grinding process. 78 pg__Manufacturing of blended cement. cement book Addeddate 11:17:13 Identifier Optimised cement design download.

The essential reference for cement producers. Fully updated in 2019 and extended with a new alternative fuels section, the Seventh Edition of the Cement Plant Operations Handbook is now available free of charge to International Cement Review subscribers.. Covering some 340 pages, the cement industrys favourite technical reference book provides indepth information of the various aspects of

Concrete Design Production. May 27 2016#183; As previously noted while there are a number of excellent books covering plant design process engineering and cement chemistry there is a fair ly sparse literature addressing cement plant operations and little to serve the hapless novitiate

cement export to these countries, because it has enough mineral resources, but there is still demand for extra infrastructure and facilities to process the material and produce the cement. Canadian cement plants make substantial contributions to their local economies through jobs, local, and taxes.

primarily suited to checking and controlling production process. The fineness of cement is measured by sieving it on standard sieves. The proportion of cement of which the grain sizes are larger than the specified mesh size is thus determined. Air Permeability Method ( Blaine Method )

Specific gravities of Portland cement and other cementitious materials, if used. Relationships between strength and watercement ratio or ratio of watertocement plus other cementitious materials, for available combinations of cements, other cementitious materials if considered, and aggregates. Procedure for ACI Method of Concrete Mix Design 1.

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter.

WhatsApp)

WhatsApp)