smallscale gold ore processing machine rsa

small scale gold ore processing machines. smallscale gold ore processing machine,rsa. smallscale gold mining equipment in south africa,used. gold ore processing machine 2 rsa SBM .

WhatsApp)

WhatsApp)

small scale gold ore processing machines. smallscale gold ore processing machine,rsa. smallscale gold mining equipment in south africa,used. gold ore processing machine 2 rsa SBM .

Small scale silver ore processing miniwindnlmall and medium scale gold ore processing small scale mining info visually, the gold bearing ore will generally be darker than the barren ore, due to the other minerals and metals present these minerals could be called quot;indior mineralsquot; if their presence signals the presence of gold or silver and placed on containers for processing later.

Mobile Gold Ore Processing Mining Equipment Supplier Price for Small Scale Rock Alluvial Diamond Mine Placer River Sand Mineral Washing Our factory professional produce different type Gold washing trommel, Rotary scrubber, Vibrating screen, Jigger machine, Knelson centrifugal concentrator,

Small Scale Gold Ore Processing Plant. Heap leaching generally requires 60 to 90 days for processing ore that could be leached in 24 hours in a conventional agitated leach processold recovery is typically 70 as compared with 90 in an agitated leach plantven with this inferior performance, the process has found wide favor, due to the vastly.

In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the primary and secondary crushing machine to crush hard or medium hard metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Small Scale Gold Ore Processing. more commonly, smallscale gold mining utilizes significant quantities of mercury to extract gold from the orexposure to mercury in these operations not only endangers miners and their families, but is also detrimental to the environment when deposited into the water supply.

small scale gold ore processing plant south africa, small scale gold processing plant south africa plant,mini gold crushing plant South Africa small gold ore processing plant equipment in south africa small scale More; stone crushing machine used in copper ore mining plant, is a professional manufacturer of openpit mining equipment,, South .

After a cycle is completed, the miner can then extract gold from the ridges of the centrifuge vessel. For small scale centrifuges, cycles usually last around hours. Operating a centrifuge takes skill as it must be tuned to the material it is processing.

Gold ore processing on small scale jaw crusher pe 750 x 1060 . pe 750 1060 jaw crusher for barite from manufacturer. pe jaw crusher machine small jaw crusher price stone. barite crusher middot limestone crusher middot bentonite crusher middot gold ore crusher middot dolomite crusher the primary jaw crushing machine also named as pe jaw crusher machine can crush all kinds of as famous china

Gold ore processing small scale electrical equipment Small Scale Gold Ore Processing Equipment mperTo improve the environmental situation in small scaBefore final discharge jigtailings flow over a coconut mat to recover remaining fine goldThe retort room is the only processing area that is not located on the More Info . . Gold Refining Systems Machines and Equipment

This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries. First, concentration

A new technology that delivers commercialscale, cyanidefree gold processing has been released by Australianbased company Clean Mining. The process replaces cyanide with a safer, less hazardous...

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten

Small And Medium Scale Gold Ore Processing. Processing smelting and refining gold with ores of higher gold content greater than 20 grams of gold per tonne of ore cyanidation is accomplished by vat leaching which involves holding a slurry of ore and solvent in large tanks equipped with agitators small scale

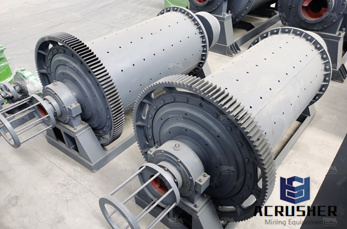

The current mainstream technology with gold Small Scale Gold Ore Processing Plant usually through beneficiation equipment crusher equipment jaw crusher crushing then into the gold processing equipment energyefficient ball mill crushed then grading machine mixing bucket chute flotation machines and other equipment treatment by reelection flotation concentrate and tailings.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore

small scale gold ore mineral processing equipment. small scale gold mineral processing equipment for gold ore . small scale gold ore mining Small scale gold ore milling equipment to refer to mining characterized by a or force that is not formally trained in mining and uses rudimentary techniques for prospecting extracting and processing of gold. Obtener precio . Appropriate Process

If YES, here is a detailed sample small scale gold mining business plan template amp; feasibility report. Mining activities include the development of mine sites and the onsite processing of ore into a concentrate or bullion. Gold and silver ore mining companies typically retain ownership of the semiprocessed gold or silver products and pay for further refining on a tollcharge basis. If

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Processing, smelting and refining gold | World Gold Council

Processing, smelting and refining gold. With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators. SMALL SCALE REFINERS;

WhatsApp)

WhatsApp)