Exploring biggest maintenance challenges in the mining

Mining equipment maintenance is so vital that a single mining venture could spend from 35% to 50% of its annual operating budget on equipment maintenance and repair alone. Such equipment

WhatsApp)

WhatsApp)

Mining equipment maintenance is so vital that a single mining venture could spend from 35% to 50% of its annual operating budget on equipment maintenance and repair alone. Such equipment

Preventive Maintenance of Mining Equipment Based on Identification of Its Actual Technical State. January 2014; DOI: /

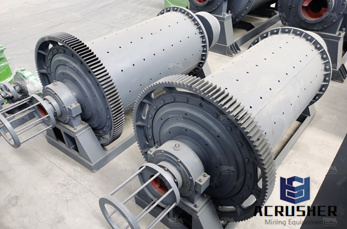

#0183;#32;A typical mining company has three important assets: the human laborforce, the orebody, and the equipment. Trucks, excavators, drilling machines, crushers, grinders, classifiers, and concentrators represent the equipment. Mining operations that want to take advantage of economies of scale have huge equipment fleet, and the worth of the equipment could be more than a hundred

Preventive and Predictive Maintenance 700ZB00102 42 Preventive/Predictive Maintenance The guiding principle of PPM is the regular and systematic application of engineering knowledge and maintenance attention to equipment

Our preventive maintenance programs are based on our intimate knowledge of our equipment, coupled with our worldwide database of mean time between failure (MTBF) information for equipment in all mining conditions, which allows us to create customized programs for your equipment. Develops planned maintenance schedules. Our planned maintenance

maintain, maintenance management has to face even more challenging situations to maintain effectively such equipments in industrial environment. This paper highlights the different types of maintenance practices: predictive, preventive, proactive, reactive being followed for mining machineries, maintenance models, TPM, Modular Mining

Underground Mining Vehicle amp; Equipment Preventive Maintenance Grace Equipment Company can cater to all your underground mining vehicle and equipment maintenance requirements. With a purpose built workshop, our team are ready to get your underground mining utility vehicle and equipment

Heavy earth moving equipment''s are critical for completion of any developmental projects. Dams, schools, bridges or any mining related initiations are part of these infrastructure development

PDF | On Jan 1, 2014, Kovalev Vladimir and others published Preventive Maintenance of Mining Equipment Based on Identification of Its Actual Technical State | Find, read and cite all the research

Preventative Maintenance For Mining Equipment. The equipment preventive maintenance schedule databases can be conveniently bought off the it must be noted that these solutions rarely conform to the different types of challenges that come with the sample preventive maintenance scheduling maintenance schedule template apartment word doc.

A complete guide to predictive maintenance,basic elements of maintenance management,cement mining maintenance training,data mining for manufacturingpreventive maintenance,equipment maintenance and replacement decision,equipment preventive maintenance software by,go big on iot value with preventive maintenance,how to winterize your mining equipment journal,maintenance lessons from the mining

Equipment used in the mining facility of Barrick Gold requires regular maintenance and experiences random failures. Maintenance and repair activities are performed in the truck shop which is composed of physical spaces referred to as bays. The goal of building a new mining

Our preventive maintenance programs are based on our intimate knowledge of our equipment, coupled with our worldwide database of mean time between failure (MTBF) information for equipment in all mining conditions, which allows us to create customized programs for your equipment. Our planned maintenance

preventive maintenance mining equipment. 5 Tips on Machinery Maintenance MT Blog. 5 Equipment Maintenance Tips to Extend the Life and ROI of Mining Manufacturing Industrial or Farming Equipment. Get Price; Heavy Construction Equipment Sales Rental Berry Tractor.

Jun 12, 2007#0183;#32;Mining machines are the giants among giants trucks with 13foottall tires, dozers with 850horsepower engines and shovels that gobble up 50 cubic yards with a single bite. This equipment

#0183;#32;What are the basic activities of preventive maintenance? Preventive Maintenance or PM is a set of inspections and tasks that help prevent equipment from failing. Keeping equipment operating improves plant capacity and throughput. Avoiding unwanted downtime helps the plant avoid unnecessary expenses and lost productivity.

The heavy equipment experts at Boyd CAT can handle all of your preventive maintenance needs in Kentucky, Southern Indiana, West ia and Southeastern Ohio. Our 24 locations are home to well

Aug 17, 2018#0183;#32;Higher productivity is the ultimate goal of your preventive maintenance routine, and its also the outcome of properly applied preventive maintenance. The following list summarizes many, but not all, of the important inspection items that lead to world class preventive maintenance. Every equipment operation has its own unique needs. An important part of every preventive maintenance...

Best Practice Maintenance Strategies for Mobile Equipment. A Conference Paper presented to the Maintenance in Mining Conference Bali, Indonesia By Sandy Dunn. March 1997 Introduction The traditional approach to maintaining mobile equipment

WhatsApp)

WhatsApp)