Underground Mining Mechanical Services, Kalgoorlie WA

WA based Minesite Mechanical Services specialise in the repair amp; rebuild of underground mobile mining machinery, skilled labour hire and used parts.

WhatsApp)

WhatsApp)

WA based Minesite Mechanical Services specialise in the repair amp; rebuild of underground mobile mining machinery, skilled labour hire and used parts.

Each segment requires the use of specific equipment, but there are several types of mining equipment that are used throughout the industry. This equipment includes excavators, draglines, drills, roof bolters, continuous miners, longwall miners, rock dusters, shuttle cars and scoops.

Mechanical Engineering Roles and Responsibilities in Oil and Gas. Mechanical engineers in oil and gas are responsible for many different aspects of the oil mining and refinement process, including designing and installing equipment, designing and overseeing large projects, and researching and developing new

is essentially surfacebased. Surface mining can be classified into two groups on the basis of the method of extraction; mechanical extraction, or aqueous extraction. Mechanical extraction methods employ mechanical processes in a dry environment to recover minerals, encompassing the specific mining methods of: Open pit mining

Isolation of hazardous energies in plant in Western Australian mining operations guideline. 5 Thermal energy the internal energy present in a system or substance by virtue of its temperature. Experienced as either heat or cold, thermal energy is commonly produced by mechanical devices (combustion

Longwall mining is used in horizontal, tabular deposits (mainly coal), the backfill plant on the surf ace to underground stopes. If ne mechanical excavation utilizing continuous miners, shearers, ploughs/plows, and so on, can be employed. In contrast, drilling and blasting are usually employed when the ore is too hard for cutting

Where there is more than one location where mining is being carried out, legislative requirements (and good mining practice) require that no air used to ventilate one working location can be used to ventilate another. This requires a number of separate circuits off the main roadways known as ventilation quot;splitsquot;.

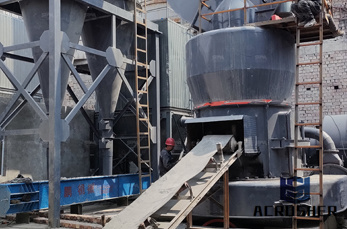

Mechanical and plant engineering . With decades of experience, thyssenkrupp continues to set the benchmark in surface mining and mineral processing: Our large bucket wheel excavators, spreaders and belt conveyors can handle up to 240,000 m#179; of overburden per day. We are also specialists in ore crushing and processing.

2 #0183;#32;Rock bolt, in tunneling and underground mining, steel rod inserted in a hole drilled into the roof or walls of a rock formation to provide support to the roof or sides of the cavity. Rock bolt reinforcement can be used in any excavation geometry, is simple and quick to apply, and is relatively

Plant can be described as being either fixed ( conveyor) or mobile ( truck). The term plant is defined in Part 1, Section 4 of the Mines Safety and Inspection Act 1994. High risk work licences are required to operate certain types of plant ( some cranes, fork lifts, elevating work platforms, boilers).

Plant Mechanics use a range of tools to diagnose faults and test machinery in order to determine what repairs need to be made or what preventative measures are required. They may work as part of a team in various industries such as mining, construction, earthmoving and agriculture.

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling. A method of separating solid particles according to size alone is called screening.

6. Hydropower Plant. In hydropower plants, electricity is generated with the help of running water. The hydropower plants display an excellent example of the use of mechanical energy to do work. In a hydropower plant, we often get to see the view of water running down the slope at an enormous speed.

Blasting equipment is used for both underground and open pit mining operations and is known to be one of the most hazardous aspects of the job. For mining operations to be successful, good blast designs are absolutely vital as poor practices and excessive explosives can result in damage to rock structures causing unwanted caving.

Coal mining has been performed since the arrival of the Industrial Revolution in the mid18th century. Coal is used as a fuel primarily for steamgenerated electrical power plants, as well as being a component of certain industrial applications, such as steel manufacturing.

What is Mechanical Energy. In physics, mechanical energy (E mech) is the energy associated with the motion and position of an object usually in some force field ( gravitational field). Mechanical energy (and also the thermal energy) can be separated into two categories, transient and stored. Transient energy is energy in motion, that is, energy being transferred from one place to another.

Grays Mining is a specialist service provider to the mining industry in Australia, the Asia Pacific Region and Africa. Our expertise is in valuing mining and related assets and providing total project solutions for the decommissioning of mine plants and the realisation of mining and related equipment, including entire mineral processing plants.

Underground mining is carried out when rocks or minerals are located at a fair distance beneath the ground. But then they need to be brought to the surface. Underground specialized mining equipment such as trucks, loaders, diggers etc. are used to excavate the material and are normally hauled to the surface with skips or lifts for further

Performance Mine Mechanical are a supplier of Labour Hire and Equipment Maintenance amp; repairs to the Mining, Civil amp; Construction industries. Our vision is that PMM shall be the preferred supplier of these services in Australia. Our main focus is safety followed by

WhatsApp)

WhatsApp)