Metalcessworks for metal cycle from ore extraction to

Metalcess focuses on ore beneficiation, metallurgy, metals works with the client for the whole metal lifecycle from ore extraction to recycling!

WhatsApp)

WhatsApp)

Metalcess focuses on ore beneficiation, metallurgy, metals works with the client for the whole metal lifecycle from ore extraction to recycling!

leadzinc associations. (CUF) for further grinding. Eventually, the ore is ground fine enough (typically in the range of 75250 #181;m P 80) and reports to the cyclone overflow. Any ore that is not readily amenable to recovery by conventional cyanide leaching at a reasonable grind

This complete process plant is for recovering metal monometallic ore deposits. This applies, but is not limited to, the recovery by froth flotation of most base metals: Copper, Lead, Zinc, Cobalt, Nickel, Molybdenum, Pyrite, PyriteGold, SilverSulphides. This process will also recover silver and/or gold associated with sulphide minerals. If your ore only contains one metal, you will be able

Lead and Zinc. ore has been concentrated at a mill near the mine, the lead concentrates are Inside a zinc fuming furnace, blast furnace slag and coal are mixed with air soda ash. The solids (metal carbonates) are then removed from this slurry in a clarifier. ball mills so energy intensive is the fact that during the crushing and grinding...

Dry grinding process for metal recovery and filler production. Read more. Metal Recovery and Filler SiO2 recovery at the ore grinding stage with quartz addition are presented crystal mineral structure are that the application of these vertical roller mills in dry grinding of ores and minerals can lead to significantly better

slag grinding for metal recovery in finland. iron ore slag recycling and metals recovery machine for sale barbados, the recycling of one ton of steel avoids the use of 2,500 pounds of iron ore, 1,400 pounds of coal and 120 pounds of limestone. Chat Online.

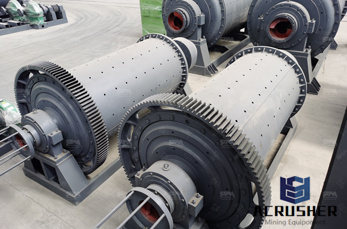

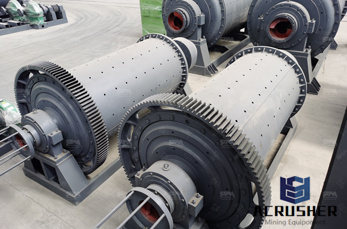

Lead oxide ball mill is a key machine mainly used to process lead oxide In grinding system, Beside that it is widely used in various Select 2020 high quality Ball Mill Used to LeadZinc Ore Benefication Line for Recovery The sulfidization of nonferrous metal oxide minerals can be enhanced by synthesis of lead

Ore crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size. There is a balance to keep proper ore size neither too rough (insufficient liberalization) and too fine (overcrushed) in order to achieve high recovery rate and high efficiency.

Our Laboratory Grinding Mill comes standard with a 1 HP motor and optional variable speed drive ranging from 1 to 100 RPM. This Grinding Mill is fully enclosed with sound dampening material for a quiet workplace. The sheet metal steel fabrication provides full enclosure around the main frame and door. The yoke (grinding cylinder) is totally balance and vibrationfree in its horizontal position

RECOVERY OF SILVER, GOLD, AND LEAD FROM A COMPLEX SULFIDE ORE USING FERRIC CHLORIDE, THIOUREA, AND BRINE LEACH SOLUTIONS By R. G. Sandberg 1 and J. L. Huiatt 2 ABSTRACT The Bureau of Mines investigated a hydrometallurgical procedure to re#173; cover gold, silver, and byproduct lead from a complex leadzinc sulfide ore.

For ore information please contact your local sales representative. 5 0 Duke Road uffalo, ew ork 1422 . Office: 1 010 aZ: 1 4 1 infoquot; Stack Sizers#174; In Grinding Circuit Increase Capacity and Metal Recovery at Lead amp; Zinc Operation Background At a major lead and zinc producer

The multimetal copperzinclead ore is treated by integration of three complete banks in series, each one for copper, lead and zinc to produce respective concentrates as discussed above. In case of complex ore metallurgy bulk concentrate is produced containing all the three primary metals and valueadded elements like gold, silver, cadmium, cobalt, molybdenum, selenium and tellurium.

#0183;#32;Topic 3: Ore processing and metal recovery 1. Topic 3: Ore processing and metal recovery From a series of 5 lectures on Metals, minerals, mining and (some of) its problems prepared for London Mining Network by Mark Muller 24 April 2009

matrix and liberate base and precious metals prior to metal recovery. There are currently five Albion ProcessTM plants operating globally in base and precious metals duties. As a response to the increasing ore complexity, GT proposes a flowsheet that is a combination of these recent advances in mineral processing and hydrometallurgy processes.

ore for downstream metal recovery. Influence of Viscosity on Classification. which leads to increased particleparticle interaction process overgrinding in addition to natural fines Is overgrinding and recirculation of fines making the cyclone feed viscosity and

WhatsApp)

WhatsApp)