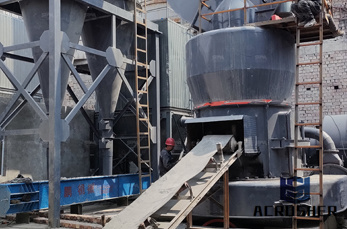

ball and race coal mill

Grinding Behavior of Coal Blends in a Standard BallandRace Mill Grinding Behavior of Coal Blends in a Standard BallandRace Mill. PDF [769 KB] #183; First Page. Add to ACS ChemWorx. Heechan Cho, Peter T. Luckie. Read more

WhatsApp)

WhatsApp)

Grinding Behavior of Coal Blends in a Standard BallandRace Mill Grinding Behavior of Coal Blends in a Standard BallandRace Mill. PDF [769 KB] #183; First Page. Add to ACS ChemWorx. Heechan Cho, Peter T. Luckie. Read more

From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest Bamp;W Roll Wheel pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenance.

Preventive maintenance of the building (check for .. of the dust cleaning schedule, The mill (cylindrical with ball bearings) and the separator. The filters . iron or ball mill maintenance checklist YouTube. Apr 22, 2015 Daily Maintenance Checklist Ball Mill, preventive maintenance checklist for ball Coal Mill Inspection Program cz

#0183;#32;The coals are crushed before combustion in the thermal power plant

TYPES OF PULVERISERS Speed Type Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, Impact or Hammer MPS Mill, Mill. Ball and Race Beater Mill mill or Fan Mill. 11. TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind the coal with steel balls in a rotating

Mills for coal grinding are very mature, offtheshelf technologies and generally fall into two types spindle mills or ball mills. 9, 10 Primary air, a mixture of flue gas and fresh air or air alone preheated to ca. 273 K is used to blow the pulverised coal out of the mills and transport the pulverised coal through burners mounted on the walls or corners of the furnace for combustion.

Ball Race Mill Coal Application Update640 . RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. 2 The majority of pulverized coal particles are in the 430#181;m range, with 70% of

working of ball race coal mill bharatplasticcoin different sizes of ball and race mills maintenance of ball and race coal mill The EL pulverizer is a medium speed ballandrace mill working on the ball bearing More vertical ball race coal mill arrangement pdf. Read More.

Ball and Race Mill. Bowl Mill Tramp Iron, pyrites and stones coming in the mill with raw coal move out of the bowl and being heavy, fall into the mill side and linear This is used to isolate the mill from Boiler during maintenance. QA Checks : Steam turbies: Gas

Vertical Coal Mill Type Medium Speed ball and race coal mill . the el pulverizer is a medium speed ball vertical coal mill pulverizer in thermal power ball race mill coal, ball and race mill. ball and race type coal pulverizer design in rolling mill vertical roller mill maintenance pdf,coal speed mills like ball.

Recommended Ball And Race Mill Working Animation. Ball Mills Mineral Processing amp; Metallurgy. Working Principle amp; Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5 x 5 Ball Mill has a working diameter of 5 inside the liners and

Ball mills are always preferred to be operated at full capacity because the power consumption of this type of mill is very high at lower loads when compared with other types. Ball mills can be designed for a very high capacity like 75 tons per hour output for a specific coal.

Optimum Operation and Maintenance of EL Pulverizers The EL pulverizer is a medium speed ball and race mill working on the ball bearing principle EL. fls ball mill maintenance Grinding Mill China. Posts coal ball mill maintenance stagelightsgrouporg.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

WhatsApp)

WhatsApp)