Chemical analysis method standards and proficiency

The chemical compositions of limonite ore and deposit samples were determined using Chinese Iron Ore Chemical Analysis Methods Standard [25]. analysis of mineral samples.

WhatsApp)

WhatsApp)

The chemical compositions of limonite ore and deposit samples were determined using Chinese Iron Ore Chemical Analysis Methods Standard [25]. analysis of mineral samples.

Hydrothermal ores These are iron ore deposits formed by hot solutions which transported iron and replaced rocks of favorable chemical composition with iron minerals to form irregular ore bodies. In these deposits, iron often occurs as siderite (FeCO3) or sometimes as oxides.

CYQUEST#174; antiprecipitants, humate removal and iron removal reagents 12 Statistical methods in mineral processing Section Petrolite, Nottingham Chemicals industrial mineral products, and Inspec (Chile) Mining Chemicals product lines in 1998 and 1999.

The simplest method of separating ore from gangue consists of picking out the individual crystals of each. the method chosen will depend on the relative physical and surface chemical properties of the mineral and the gangue. The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present.

4. What type of mineral is gold? Ans: Gold has almost always traced of silver in its natural mineral form, and it can also contain traces of copper and iron. 5. What are the main ores of zinc? Ans: Sphalerite (zinc blende), a mineral of zinc sulphide, is the most common zinc ore. You now know about ores and minerals.

The first iron mining techniques used charcoal which was mixed with iron ore in a bloomery. When heating the mixture and blowing air (oxygen) in through bellows, the iron ore is converted to the metal, iron. The chemical reaction between iron oxide and carbon is used here to produce iron metal. The balanced chemical equation for the reaction is:

physical and chemicals methods iron ore to refine the mineral. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent. Agitation Tank For Chemical

#0183;#32;Another alternative ironmaking method, smelting reduction, had its forerunners in the electric furnaces used to make liquid iron in Sweden and Norway in the 1920s. The technique grew to include methods based on oxygen steelmaking converters using coal as a source of additional energy, and in the 1980s it became the focus of extensive research and development activity in Europe,

Features Library consists of a complete list of the various mining industries that cover, such as coal, diamonds, ironore, besides others, as well as Corporate Profiles and Top

#0183;#32;Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process. In its natural form, iron ore has a reddish hue

mineral processing [zircon, ilmenite, magnetite iron ore, garnet] and iron ore Mining and Minerals | International Protective Coatings The mining market covers the extraction, pretreatment, processing amp; refining and transportation of minerals such as gold, copper, coal, potash and aluminium.

iron ore was not significantly affected at high microwave power, high H 2SO 4 and H 2O2 concentration and high temperature conditions. By applying microwave and chemical methods (H 2SO 4/H 2O2) together, sulfur content of iron ore was removed approximately by 84%. Keywords: Iron ore; sulfur removal; physical and chemical methods.

The process of refining rough or polished diamonds includes cleaning diamonds initially. Strong solutions such as alcohol, hydrogen peroxide, acetone and sulphuric acids with or without diluted water are used. These solvents are used to remove imp...

Equipment Used For Mining Iron Ore. Extracting And Refining Methods Used For Mining Iron Ore. 2011 02 mining iron ore mining iron ore process of separating the iron from the non iron material the magnetic iron ore is then a clay from wyoming used to help iron ore concentrate stick together when rolled into. Read More

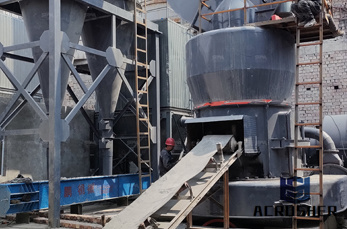

Fig 1 A typical flow sheet of iron ore beneficiation plant. Some of the common methods/techniques applicable for iron ore processing are described below. Crushing, grinding and screening technique. The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and recover the valuable minerals.

R. Stace, in Iron Ore, 2015. Abstract. Iron ore reserves are normally found within a few meters from the ground surface, and most of the major mines of the world are operating an opencut system, which requires little sophistication, except in terms of the equipment used and the quantities needed to be mined for operations to be costeffective. This chapter will look at case studies that define

#0183;#32;Iron ores are refined in the blast furnace. The product of the blast furnace is called pig iron and contains about 4% carbon and small amounts of manganese, silicon, phosphorus, and sulfur.

#0183;#32;The purpose of this study is to develop a practical modal analysis technique for the iron ore and process samples of the Malmberget deposit and processing plant. The developed element to mineral conversion technique uses, in addition to the chemical assays, the mineral diagnostic method, Satmagan analysis. Three data sets are used.

WhatsApp)

WhatsApp)