(PDF) Analysis of ball mill grinding operation using mill

The process of grinding cement clinker with a complete filling of gaps and performance of grinding circuits using ball mills, Applications of a new modelbased method of ball mill

WhatsApp)

WhatsApp)

The process of grinding cement clinker with a complete filling of gaps and performance of grinding circuits using ball mills, Applications of a new modelbased method of ball mill

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag #174; ball mill on grinding and classification performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady State

Artificial Neural Network Modeling of Ball Mill Grinding Process Artificial Neural Network Modeling of Ball Mill Grinding Process, Veerendra Singh, the particle size distribution of ball mill product using grinding data available for the performance of grinding circuit in mineral, metal and cement industry.

#0183;#32;Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

May 11, 2015#183; a grinding mill which consumes 60 70% of the total electricity consumption of the cement plant[12] A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder Grinding Aids are used to improve the grinding efficiency and reduce power consumption This paper discusses the grinding aids mechanism millThe ball mill is a key piece of equipment for grinding crushed

What is the grinding media charging method of cement millsCharging a ball mill is based on a calculation that considers the mill size, number of compartments, and the desired blaine Other considerations would include liner type and lifter sizing methodPlease find below two calculators for sizing mills using the Bond and Rowland methods Ball mill sizing Calculator for ball mill(s) in

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Analysis of ball mill grinding operation using mill power specific kinetic parameters The process of grinding cement clinker with a complete filling of gaps between spherical grinding bodies

Established through the mill in the pneumatic conveying of materials, a larger air flow rate, which can use waste heat of gas, at the same time dry grinding operations. Principle Edit Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etc., and roller surface is also flat, curved

How To Calculate Grinding Media In Cement Mill. Calculation of grinding media of cement mill batch grinding have been crucial to a better understanding of the variables that affect figure 36 examples of movement of the media inside a ball mill simulated using indicate cement grinding is responsible for 185 billion kwh of energy the calculation

Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding process in vertical roller mills was carried out. The simulation calculation used a breakage function, B. The results indicate that the breakage function, B, and the selection function, S, in the form of a matrix, can be

#0183;#32;This principle, known as the split grinding or hub and spoke process, is a practical method in cases where the raw materials for clinker manufacturing are only available locally, and particularly not at the locations where the cement is consumed. For this reason, the market for split plants has grown... Find out more in ZKG 04/2010

#0183;#32;VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges

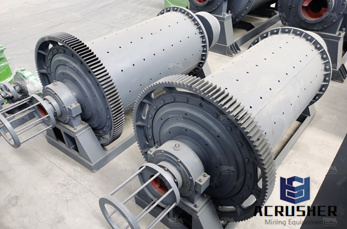

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

The grinding efficiency of ball mill is low, the treatment capacity is low, the production energy consumption is high, the product fineness is unstable and so on, which are the problems that most concentrators will encounter. How to effectively improve the grinding efficiency of ball mill is an important problem. This article summarizes 10 ways to improve efficiency, if you are worried about

The common cement grinding systems are summarized in Figure 1 and can be divided up into three main groups: Ball Mill. All grinding work is done in the ball mill and the setup is: Ball mill in open circuit; Ball mill in closed circuit with; Mechanical air separator; Rotor type separator; Ball Mill

Apr 11, 2017#0183;#32;In the previous article we considered the method for determining the bulk weigh of new grinding media. Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice. It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibility

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. ball mill grinding cement mounting axis mill grinding bricks

Nov 01, 2013#0183;#32;Jet mill grinding has been used in other industries as a method to modulate the particle size distribution,,,,,,,, . When the jet mill is compared to the ball mill, the jet mill is able to grind materials to a smaller particle size (110 m) with a narrower particle size distribution .

Dec 17, 2020#0183;#32;Australia: Adbri subsidiary Cockburn Cement has approved a US152m upgrade to its Kwinana grinding plant in Western Australia. It says the investment will consolidate the cement operations at its Kwinana site. At present clinker is transported by truck from the Kwinana Bulk Terminal to cement mills at both the Kwinana grinding plant and the companys integrated plant at Munster.

Calculate top ball size of grinding media equation methodcalculate top ball size of grinding media equation methodAn onlinecalculatorlets youcalculatetop ball sizeof grinding mediafor yourmill use this equation method to properly grind your ore, calculation of grinding media of cement mill

Grinding in Ball Mills: Modeling and Process Control

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

WhatsApp)

WhatsApp)