Production of metallurgicalgrade silicon from Egyptian

PDF | On Feb 22, 2018, Ali, ElSadek, Morsi, ElBarawy, and AbouShba published Production of metallurgicalgrade silicon from Egyptian

WhatsApp)

WhatsApp)

PDF | On Feb 22, 2018, Ali, ElSadek, Morsi, ElBarawy, and AbouShba published Production of metallurgicalgrade silicon from Egyptian

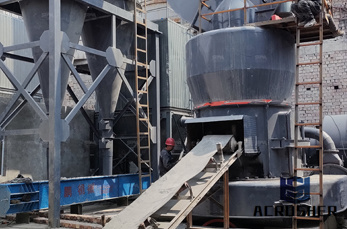

The process of unloading, cooling and solidifying the silicon into the oven is called Metallurgical Grade Silicone (MGS). The process begins by charging it with quartzite and carbon in an arc furnace and then with carbon dioxide (CO2) in a gas chamber. [Sources: 6, 12]

29/03/2016#0183;#32;PyroGenesis PUREVAP QVR disruptive potential is its one step direct transformation of Quartz into Solar Grade Silicon Metal, thereby potentially allowing Uragold to manufacture Solar Grade Silicon Metal (Sg Si) at the same cost as producing Metallurgical Grade Silicon Metal (Mg Si), a much lower quality product. Additionally, the Company believes the process holds a significant capital cost

29/03/2016#0183;#32;PyroGenesis PUREVAP QVR disruptive potential is its one step direct transformation of Quartz into Solar Grade Silicon Metal, thereby potentially allowing Uragold to manufacture Solar Grade Silicon Metal (Sg Si) at the same cost as producing Metallurgical Grade Silicon Metal (Mg Si), a much lower quality product. Additionally, the Company believes the process holds a significant capital

Softening and Melting of SiO2, an Important Parameter for Reactions Quartz (SiO2) is the main silicon source for production of metallurgical gradesilicon in submerged arc furnaces. During heating in the furnace, quartz will first... Get Quote.

v118n2a7 Production of metallurgicalgrade silicon from Egyptian quartz. 91736,.07461. Metallurgicalgrade silicon (MGSi) is an important metal which has a range of diverse industrial applications such as a deoxidizer in steelmaking industry, alloying element in the aluminum industry, the preparation of organosilanes, and the production of hyper pure electronic grade silicon (gt;% Si), which is used

Silicon as it is used in semiconductor manufacturing, is made up of quartz. Oxygen which reacts very fast with silicon even at room temperature, and which is present in quartz associated with silicon as silicon dioxide SiO 2, must be removed. This is done just above the melting point of

production of metallurgical silicon from quartz FullText Paper (PDF): Extraction of Metallurgical Grade Silicon (MGS) from RawMineral Quartz availe in Pakistan. Get Quote from quartz to

from quartz are as follows: bulk production of metallurgicalgrade silicon via carbothermic reduction in a submerged furnace, refining of metallurgicalgrade silicon via the chemical means to polycrystalline silicon, or through the metallurgical route to solargrade silicon, wafer manufacturing, and, lastly, silicon solar cell manufacturing.

01/01/2012#0183;#32;Jafar Safarian et al. / Energy Procedia 20 ( 2012 ) 88 #226; 97 89 1. Introduction Metallurgical grade silicon (MGSi) is the initial material to produce pure silicon for photovoltaic and electronics applications. It is commercially produced through the reduction of silicon oxide (quartz) with carbon in submerged arc furnaces [1].

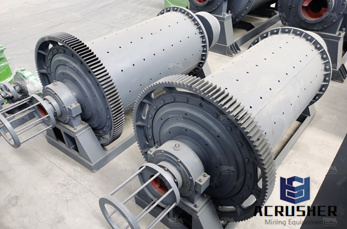

Metallurgicalgrade silicon (MGSi) was successfully produced by carbothermic reductionsmelting of Egyptian quartz using a mixture of carbonaceous materials in a locally made semipilot submerged...

Silicon, ferrosilicon and other silicon alloys are produced by reducing quartz, with coal and iron or other ores at very high temperatures (2000#176;C) in electric arc furnaces. 385 Some silicon gas (or fume) is produced in the process and reaches the top of the furnace with other combustion gases, where it becomes oxidised to silica by the air and then condenses as submicroscopic particles and

metallurgical silicon in the mid2000s served as a testing ground for using higher purity quartz (usually of smaller grain size resulting from chemical cleaning) for mgSil production as a way to bypass or circumvent the traditional polysilicon process. Many experiments were performed and

These include hydrogenated amorphous silicon and upgraded metallurgicalgrade silicon (UMGSi) used in the production of lowcost, largearea electronics in applications such as liquid crystal displays and of largearea, lowcost, thinfilm solar cells. Such semiconductor grades of silicon are either slightly less pure or polycrystalline rather than monocrystalline, and are produced in comparable quantities as the monocrystalline silicon

MetallurgicalGrade Silicon Production Quartz sand is reduced with carbon in an electric arc furnace at temperatures gt; 1900#176;C to metallurgical grade silicon (gt; 98 % pure). The major part of the world production (2008: approx. 6 million tons) is used for manufacturing alloys with aluminium and steel, and as raw material for polysiloxane production.

Of the million tonnes of metallurgical silicon produced in 2010, 12 % was for the production of silicon solar Metallurgical (MG) silicon is produced at the rate of millions of tons/year at a low economic cost of few /kg and an energy cost of 1416 kWh/kg.

of production of metallurgical silicon from quartz. of production of metallurgical silicon from quartz Production of metallurgical grade silicon from Egyptian quartz Feb 01 2018 Metallurgical grade silicon (MG Si) was successfully produced by carbothermic reduction smelting of Egyptian quartz using a mixture of carbonaceous materials in a locally made semi pilot submerged.

material for the metallurgical production of ferrosilicon and silicon metal. This includes defining mechanical properties important for the size reduction experienced during transport and storage and thermomechanical properties of quartz that is important for how the quartz

WhatsApp)

WhatsApp)